The Easy Way to Paint Your Guitar

There are many ways to paint a guitar body, some are simple, some are multi-staged and hard to follow. With this tutorial we will going to try to do it simple and hopefully you will be able to paint your guitar body without wanting to kill me.

The easiest way is buy aerosol cans of paint in Nitorlack Guitar Coatings. You can choose any of the popular Fender or Gibson colors and look for a lot of guides and tutorials about how to paint your guitar easy.

Here are the necessary steps and tips to follow to paint a guitar in Black Gloss but you can do it in any other color:

1. Preparation of the Guitar

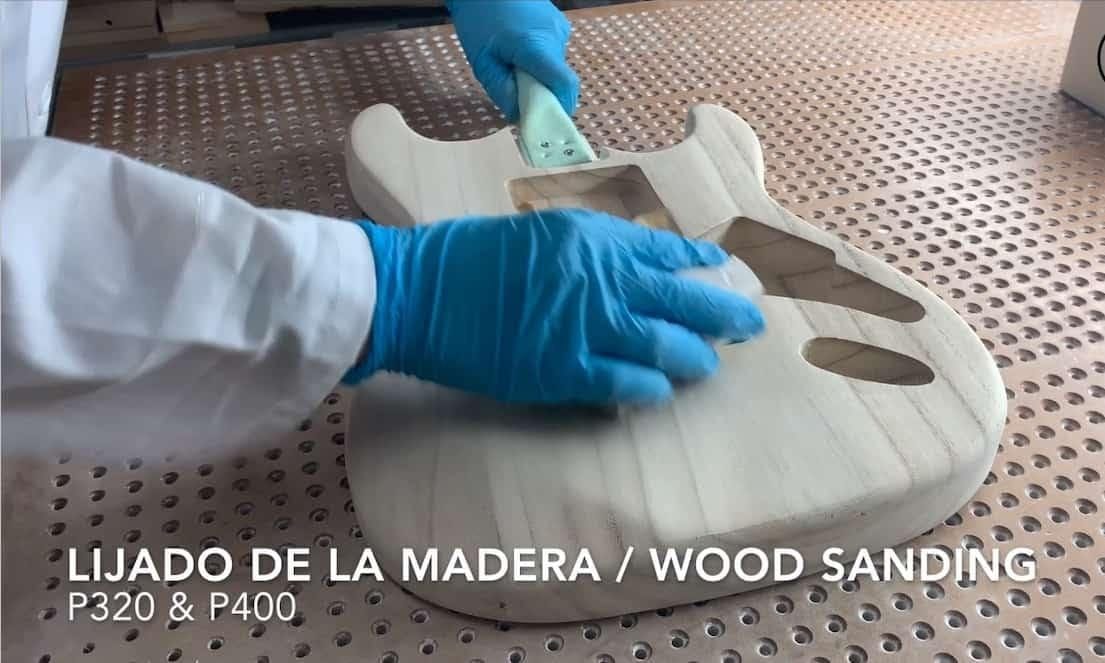

The wood must be free of imperfections and stains.

The woods with a lot of pore like ash or mahogany, whenever a closed pore finish is desired, a grain filler must be applied to fill the pore, this product can be found in our store.

Once the pore is filled, or in case of woods with little pore, we sand with P400 grain to obtain a uniform surface, always in the direction of the grain.

The objective of this first step is to obtain a perfectly smooth surface without defects or roughness to proceed with the application of the first coats of primer.

2. Application of the White Primer - Nitorlack Primer White

The base coat is the layer of varnish that will build the base of the finish, providing a uniform surface.

We will sand with P800 grain between coats. At least 3 coats are recommended. We will apply the product until we see that there are no imperfections, it is perfectly level and the pore of the wood is completely closed.

3. Color Black Gloss (or other Nitorlack Color)

We apply layers of BLACK GLOSS color sanding between them with P800 leaving to dry 24 hours between coats. It is recommended to apply a minimum of 2 coats, until the entire background is covered and we see that the color is completely uniform.

Be especially careful when sanding the first coats of color to avoid peeling.

4. Gloss Finish - Nitorlack Lacquer

The application process of the finish is the same as the base coat. We apply coats of finish sanding between them with P800 leaving to dry 24 hours between coats. It is recommended to apply a minimum of 3 coats.

Once we see that the finish is completely uniform and the guitar is finished to our liking it is important NOT TO SAND the last coat that we have applied and let it dry for 2 to 3 weeks to polish and get the maximum brightness.

5. Polishing

Sand to the water with a gradual process with sandpaper 1200-1500-2000 until all the imperfections of the application disappear.

Try to sand in straight line without exerting too much pressure to avoid making deep marks that will be difficult to remove with the polish. It is advisable to apply a few drops of soap to the water to facilitate the sanding.

Apply a few drops of polish on the surface of the guitar and on the polishing sponge.

It is recommended to polish at 1500 to 2000 rpm without pressure to avoid overheating the finish. Check the heating regularly during polishing.

Perform a first polishing process with the white sponge and finish with the black sponge until a mirror shine is achieved.

Clean with a cloth the remains of polish and the guitar will be finished.

Tips and General Recommendations

A finish with "Nitorlack" lacquer for guitars, depending on factors such as whether the wood is stained or not, and how many coats of color are given, should have a total of 6 to 10 coats in total, counting background - color - finish, with a minimum of 3-4 coats of gloss finish. This will give a thickness of approximately 150 microns (0.15 mm) depending on how much sanding is done, how much lacquer is applied in each coat and what thickness of finish is desired. If you have not finished an instrument before, it is advisable to apply 9 to 12 coats, so you will be sure not to sand or polish the finish too much, leaving parts with "bare" wood. As more experience is acquired with the product and the finishing method, fewer coats will be necessary and finer finishes can be achieved.

If you accidentally get a "drop" or "drip" during application, allow the finish to dry for 24 hours and level by sanding with P400 sandpaper, preferably on a hard sanding block. The drip can also be "cut" with a razor blade, a faster method and one that avoids the accidents that can be caused by excessive sanding. To become familiar with the process, it is advisable to test on discarded wood, in order to evaluate for yourself the characteristics of the process of finishing a guitar with "Nitorlack" lacquer guitars.

It is also advisable to use a "witness" surface on which to apply the layers of lacquer at the same time as on the piece to be finished. A paper glued with masking tape to a rigid support (wood, thick cardboard) is a suggestion. Thus, measuring first the thickness of the paper with a caliper and then measuring the resulting thickness of the successive layers once dry, you will have a fairly accurate idea of the thickness of the layer to be applied and thus be able to have a better idea of its thickness. A thickness of 150 to 180 microns (0.15 to 0.18 mm) guarantees a fine finish that respects the vibrations of the instrument and protects it, avoiding excessive thicknesses.

Always apply thin coats. Let dry 24 hours and sand between coats. Apply in crossed coats to distribute the product well. Apply with an approximate distance of 15 to 20 cm.

Safety Recommendations

Apply in ventilated or extracted places. Wear protective gloves, clothing, goggles and mask. Wash thoroughly after handling. In case of contact with eyes: Rinse thoroughly with water for several minutes. Remove contact lenses when present and easy to do so. Continue rinsing. Highly flammable liquid and vapors.

This process can be equally useful to paint your guitar in other colors and with other dyes.

With our experience we can say that the colors that our customers like the most are SEAFOAM GREEN and FIESTA RED.

If after reading this article you still have doubts about how to paint your guitar, do not hesitate to contact us on our website, and a professional will help you.

Nitorlack

Manufacturers of wood paints for 50 years. As a result of our experience and specialization we have become specialists in nitro lacquer and varnish for guitars . They are used by both the amateur, and by the best luthiers and guitar makers.